Cloud

Internet of Things (IoT) in global public clouds - six lessons learnt

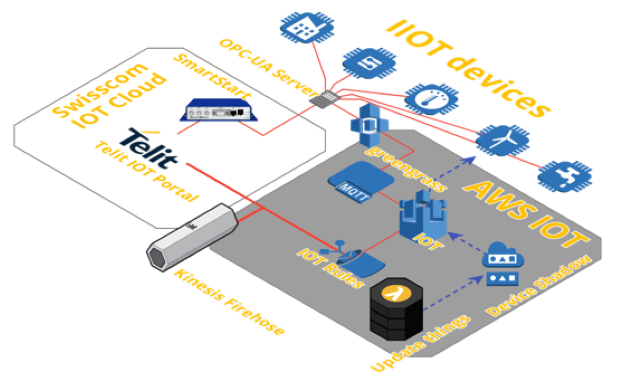

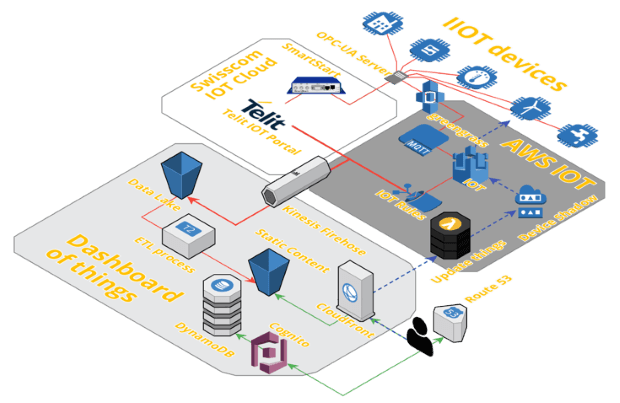

The Swisscom Global Public Cloud AWS Tiger team has been working intensively on the Industrial Internet of Things. We have built an IIoT PoC to prove the feasibility of some key technical challenges for a future platform that has ten million machines and multiple geographic locations as a prerequisite. We also need to be able to scale with hundreds of thousands of users and tens of thousands of manufacturers of things. We've been looking at the OPC UA open standard, edge gateways and analytics streams. We have learnt a few lessons for the new manufacturing with IIoT in the global public clouds that we want to share.