5G in industry

At Ypsomed, 5G is already a reality

The future of the factory was already clear in March, in Solothurn. In collaboration with medical technology manufacturer Ypsomed, Swisscom is testing the use of 5G in industrial environments.

Ypsomed is the leading developer and manufacturer of pens, auto-injectors and pump systems for administration of liquid medication. Ypsomed was the first industry partner of Swisscom to test the new 5G mobile communications generation in ongoing production. As part of the pilot project, Ypsomed has digitalised its production processes for injection pens across the entire value chain.

Ypsomed uses the 5G technology to digitalise goods tracking throughout the production process. This is made possible by indoor localisation. Further applications include real-time evaluation of machine data, virtualisation of computer resources and quality inspection by means of augmented reality technologies.

Getting jobs back to Switzerland

In Mexico, production requires several hundred employees and a huge area. Thanks to the possibilities that 5G has to offer, the same performance can be achieved with a fraction of the resources. Ypsomed’s production generates an enormous amount of data which needs to be processed immediately. “To be able to bear the costs in Switzerland, the machine has to run without interruption around the clock, or it would not pay off,” explains Ypsomed CEO Simon Michel.

Simon Michel makes no secret of it: fully automated production calls for fewer but better qualified employees. That is why productions which were outsourced in the 1980s and 1990s are being moved back from low-cost developing countries to highly developed industrialised countries. “It’s the last chance for Swiss industry,” says the CEO.

Specific applications with 5G

Localisation in the production chain

Ypsomed’s machines produce, for example, insulin pens for people with diabetes. These ballpoint pen-sized syringes undergo an automated process, are localised in real time during the production steps and are available in SAP. Sensors on the crates and a local 5G Mobile Edge Cloud make this possible at Ypsomed. If a product is not in the correct location, the system will raise an alarm. A formerly tedious process which involved scanning bar codes now runs automatically and in real time.

The position data of raw materials, semi-finished products and completed products is processed on a reserved network slice and forwarded to SAP in the Mobile Edge Cloud.

Real-time data analysis

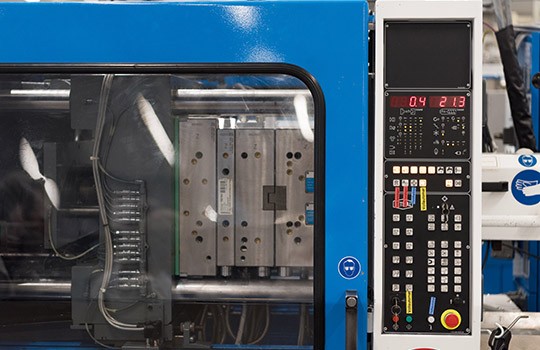

Ypsomed’s production machines must run without interruption to produce to as high a quality and as cost-effectively as possible. Owing to a software solution implemented in the local Mobile Edge Cloud, 5G generates huge data volumes (such as temperature and production data) on the production machines in real time. Predictive management can also be carried out by analysing the data: for example, it is possible to predict when a particular part of a production plant will need to be replaced or repaired. This can prevent failures and makes it possible to schedule replacement or revision of a machine.

The injection moulding machine produces data.

Virtualisation

Until now, each machine has had its own integrated computer. In a production environment networked via 5G, the software no longer runs in the machine, but is virtualised on the Mobile Edge Cloud. This enables employees to gain access to every machine via a tablet and move freely in the production hall. Ypsomed therefore saves on hardware, software and maintenance costs.

In a production environment networked via 5G, the software no longer runs in the large machine, but is virtualised on the Mobile Edge Cloud.

Quality assurance with augmented reality

Ypsomed regularly conducts quality assurance tests. Until now, employees would test products at a test centre and subsequently enter the data in the SAP in the office. Using augmented reality glasses, employees now check quality directly in the hall. This development has simplified and accelerated the quality assurance process immensely.

Augmented Reality simplifies visual quality controls, such as with holographic glasses (HoloLens).

Developing 5G together

“Cooperation with companies is very important in the development of 5G. It requires mobile communication knowledge and software knowledge, both of which Swisscom has. It also requires domain knowledge, which the customer has. Only together can they develop promising 5G solutions. 5G is the next major step in technology, which, in addition to more efficient processes, will enable completely new applications,” states Simon Michel, CEO of Ypsomed.

«5G will be the next major step in technology.»

Simon Michel, CEO of Ypsomed

“The results we have achieved in production at Ypsomed with 5G have exceeded our expectations and given us a first impression of what the future will bring,” says Heinz Herren, CIO and CTO of Swisscom.

«The results have exceeded our expectations.»

Heinz Herren, CIO and CTO of Swisscom

5G Gateway. What is more, a 5G base station, of which there are only a handful in Switzerland, offers something which still fills entire basements in many places: the entire IT department. 5G also enables seamless operation directly from the Cloud.

5G Glossary

Mobile Edge Computing

Mobile Edge Cloud is a technology with which computing resources are located directly at or in the 5G base station. It builds on the concept of general Edge computing. This enables IT processes in production to be controlled locally and directly. This, in turn, drastically increases the response time across production.

Network Slicing

Use of network slicing gives individual applications reserved and guaranteed network capacities. This is crucial for factory operations; even a brief network fluctuation can halt production and result in high losses. A network slice guarantees that all data between the machine and the Mobile Edge Cloud is only transported locally. This means within the factory, via the mobile network and not, as with conventional mobile data, via the entire public network.

Response time or latency

Response time or latency refers to the amount of time it takes to broadcast a data packet from a sender (usually the mobile phone or the IoT device) to the recipient (application or database). The end-to-end latency also includes the amount of time it takes to broadcast the receiver’s response to the original transmitter.

Virtualisation

Virtualisation describes the universal concept whereby applications can be installed and operated independently of specific hardware. In recent years, virtualisation has, in general, gone hand in hand with centralisation. This means that applications were installed on cloud data centres rather than on selected server hardware locally on the customer’s premises. Independent installation of software onto any hardware enables better use of the hardware.

Newsletter

Would you like to regularly receive interesting articles and whitepapers on current ICT topics?